Full Sizes groove end pipe Fire Sprinkler pipe

Detail Information

Rolled Groove End Steel Pipe General Information

Key Features of Rolled Groove End Steel Pipes:

Quick Installation: The grooved connection allows for rapid assembly and disassembly, which can significantly reduce installation time and labor costs.

Flexibility: Grooved systems can accommodate movement, expansion, and contraction, which is beneficial in buildings where these factors are present.

Durability: Steel pipes are robust and can handle high pressures, making them suitable for fire suppression systems.

Corrosion Resistance: When coated or lined properly, steel pipes can offer good resistance to corrosion, enhancing the longevity of the system.

Wide Range of Sizes: These pipes are available in various diameters and lengths to suit different design and flow requirements in fire sprinkler systems.

Common Sizes:

The sizes typically range from 1 inch to 12 inches in diameter, with the most common sizes being:

1 inch (25 mm)

1.25 inches (32 mm)

1.5 inches (38 mm)

2 inches (50 mm)

2.5 inches (65 mm)

3 inches (80 mm)

4 inches (100 mm)

6 inches (150 mm)

8 inches (200 mm)

10 inches (250 mm)

12 inches (300 mm)

Applications:

Commercial Buildings: Offices, shopping malls, and other commercial properties.

Residential Buildings: High-rise apartments and housing complexes.

Industrial Facilities: Warehouses, manufacturing plants, and storage facilities.

Institutional Buildings: Hospitals, schools, and government buildings.

Standards and Certifications:

These pipes often adhere to various standards and certifications to ensure they meet safety and performance requirements, such as:

ASTM A795: Standard for black and hot-dipped galvanized welded and seamless steel pipe.

FM Approved: Ensuring the pipe meets fire safety standards.

UL Listed: Certification for fire safety compliance.

|

Commodity

|

Fire sprinkler ERW carbon steel pipes |

|

Usage | construction, building material, fire sprinkler steel pipeline | |

Length | 5.8m, 6m or cut into other length according to PI | |

Certificates international standard | ISO 9000-2001, UL certificate | |

Standards | ASTM A795, ASTM A53, GB/T3091, etc | |

|

Technique

|

Welded

|

|

Surface | Galvanized or Painted to prevent the rust | |

Pipe ends | Plain or threaded with sockets/coupling and plastic cap or grooved with caps | |

|

Packing

|

In bundles, or request.

|

|

Marking | As requested in PI, for example "UL LISTED YOUFA SCH10 / SCH40" | |

ASTM A795 ERW Carbon Steel Tube Standard Specifications Reference

NPS | DN | Outer Diameter(mm) | Schedule 10 | Schedule 40 | ||||

Wall Thickness (mm) |

Unit Weight (kg/m) | Test Pressure (kpa) | Wall Thickness

(mm) | Unit Weight

(kg/m) | Test Pressure (kpa) | |||

|

1/2"

|

15

|

21.3 |

-

|

- | - | 2.77 | 1.27 | 4800 |

|

3/4"

|

20

|

26.7 | 2.11 |

1.28 | 4800 | 2.87 | 1.69 | 4800 |

1" | 25 | 33.4 | 2.77 | 2.09 | 4800 | 3.38 | 2.50 | 4800 |

1-1/4" | 32 | 42.2 | 2.77 | 2.69 | 6900 | 3.56 | 3.39 | 6900 |

1-1/2" | 40 | 48.3 | 2.77 | 3.11 | 6900 | 3.68 | 4.05 | 6900 |

2" | 50 | 60.3 | 2.77 | 3.93 | 6900 | 3.91 | 5.45 | 6900 |

2-1/2" | 65 | 73 | 3.05 | 5.26 | 6900 | 5.16 | 8.64 | 6900 |

3" | 80 | 88.9 | 3.05 | 6.46 | 6900 | 5.49 | 11.29 | 6900 |

4" | 100 | 114.3 | 3.05 | 8.37 | 8300 | 6.02 | 16.09 | 8300 |

5" | 125 | 141.3 | 3.40 | 11.58 | 8300 | 6.55 | 21.79 | 8300 |

6" | 150 | 168.3 | 3.40 | 13.85 | 6900 | 7.11 | 28.29 | 8300 |

8" | 200 | 219.1 | 4.78 | 25.26 | 5500 | sch30 7.04 | 36.82 | 8300 |

10" | 250 | 273.1 | 4.78 | 31.62 | 4800 | sch30 7.8 | 51.05 | 6900 |

Pls don't hesitate to contact us if you need other sizes. | ||||||||

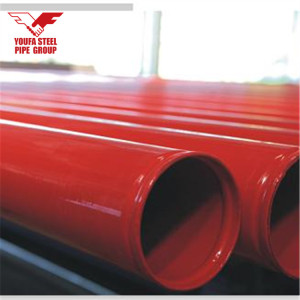

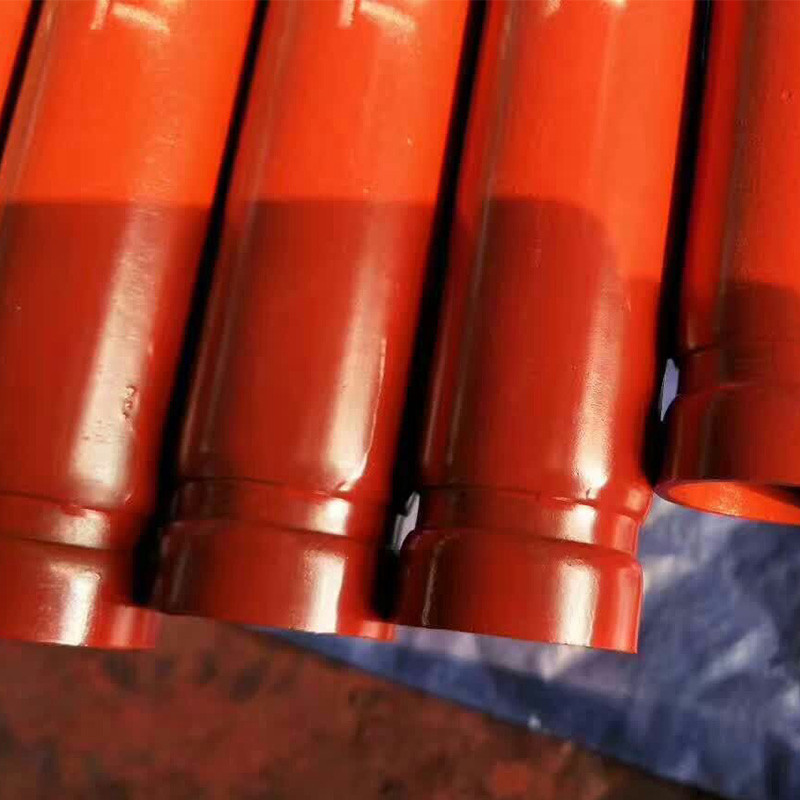

ERW Carbon Steel Fire Sprinkler Pipes Surface and Pipe Ends

Surface: Painted Ral3000 or other color

Pipe Ends: Grooved with caps

Surface: Zinc coated 30um or above

Pipe Ends: Grooved with caps

Surface: Zinc coated 30um or above

Pipe Ends: NPT threaded with coupling and cap

Surface: Painted Ral3000 or other color

Pipe Ends: NPT threaded with coupling and cap

ASTM A795 Fire Sprinkler Pipes Test and Quality Control

Chemical Composition |

for Type E (electric-resistance-welded pipe)

|

|||

|

C, Max, %

|

Mn, Max, % |

P, Max, %

|

S, Max, %

|

|

|

Grade A

|

0.25

|

0.95 |

0.035

|

0.035

|

|

Grade B

|

0.30

|

1.20 |

0.035

|

0.035

|

Mechanical Properties |

for thickness sch10 and sch40

|

||

|

Tensile strength, min [MPa]

|

Yield strength, min [MPa]

|

Elongation, min, %

|

|

|

Grade A

|

330

|

205

|

24

|

|

Grade B

|

415

|

240

|

24

|

Related Products

Review

- Loading...

Please send your message to us

Dear business customer, we are committed to providing you with professional pipeline and scafffolding product consultation and discounted wholesale prices, and look forward to becoming a long-term reliable partner!

- *Name

- *Phone

- *Title

- *Content

subscribe:

Please send your message to us

Dear business customer, we are committed to providing you with professional pipeline and scafffolding product consultation and discounted wholesale prices, and look forward to becoming a long-term reliable partner!

- *Name

- *Phone

- *Title

- *Content