What is3PE & FBE

3PE (3-Layer Polyethylene) and FBE (Fusion Bonded Epoxy) are two forms of coatings applied to pipes and pipelines in the oil and gas industry to slow or prevent corrosion.

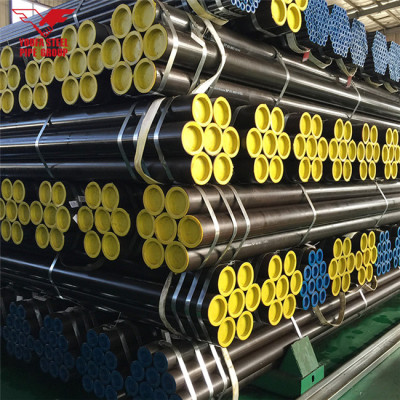

3PE is a three-layer coating that consists of an epoxy primer, a copolymer adhesive, and a polyethylene topcoat. The epoxy primer provides a good bonding surface for the copolymer adhesive, which in turn provides a bonding surface for the polyethylene topcoat. The three layers work together to protect the pipe from corrosion, abrasion, and impact damage.

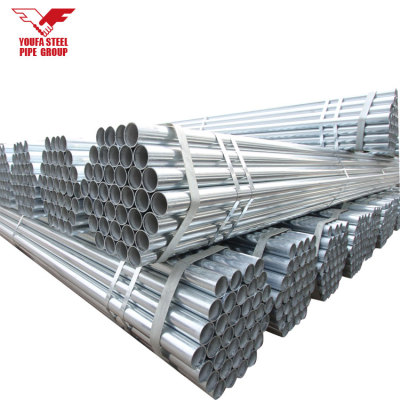

FBE, on the other hand, is a two-layer coating system that consists of a particulate-filled epoxy resin base and a topcoat that is a polyamide. The particulate-filled epoxy provides excellent adhesion to metal surfaces, while the topcoat provides excellent chemical resistance and abrasion resistance. FBE coatings are used in a variety of applications, ranging from oil and gas pipelines to water and wastewater systems.

Both 3PE and FBE coatings are effective at protecting pipelines and pipes from corrosion, depending on the specific application requirements. The choice between the two is typically driven by factors such as the type of pipeline, the operating conditions, and the cost.